|

Why simulate a thermoforming process?

- Reduce the design time for your products.

- No need to perform expensive trial-and-error procedures.

- Select an optimum design from many possible alternatives.

- Get optimum thickness distribution on final product via temperature setup on the sheet.

- Design pre-distorted images for in-mold decoration process.

|

DOWNLOAD PRESENTATION

(7 MBytes)

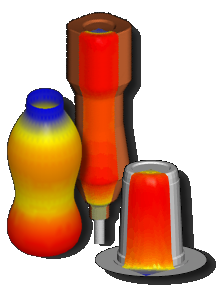

Verification analysis of a plug

assist thermoformed part

through

computer simulation

Courtesy of Tom Bush,

Fabri-Kal Co., USA

|

Features of T-SIM

- WLF temperature dependency.

- Simulates positive / negative forming with / without plug assistance.

- Time dependent deformation is described by viscoelastic K-BKZ model.

- Three different damping functions for a better material data fit (strain hardening).

- Material database containing PE, PP, PET, PC, PMMA, etc.

- Imports general 3D molds from IGES, VDA-FS via stereolithographic STL file, DXF or Patran Neutral file.

- All molds movable (up to 10 tools can be used in one simulation project)

- Time dependent sheet sagging included.

- Friction between stretched plastic material and tools.

- Heat transfer between material / tools and material / air.

- User-friendly setup of technological parameters with graphic.

- Windows context sensitive help, tutorials and hands-on examples.

- OpenGL included, allowing dynamic image rotation, zooming and panning. This enables fast shading or wireframes and contact visualization options.

- Easy, completely editable setup of T-SIM project for solver. Tight connection between initial project and result files.

- Many typical thermoforming problems solved and distributed on installation CD.

Material

- T-SIM uses time dependent, viscoelastic K-BKZ model.

- Data of frequently used polymers are available in the T-SIM material database.

- Any material can be tested (cooperation with IKP Stuttgart, Germany, or DatapointLabs, USA)

and its data imported into T-SIM.

Solver

- Very fast iterative multithreaded solver gets use of parallel processing on PC with more than one processor.

- Upper limit of sheet elements or mold elements is limited only by PC memory available.

- Fast contact analysis.

- Solving a set of thermoforming problems in a batch mode. This enables automatic case study solution.

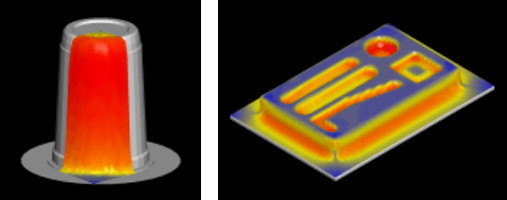

Results

- 3D cuts.

- 3D color maps of thickness, temperature, stress, extension.

- Investigate contact between plastic material and molds.

- Easy refinement of the grid in 3D areas of interest from the post-processing window.

- Export results for structural analysis to Ansys, IGES, DXF, Cosmos/M or Patran files.

- Output to Patran format enables structural analysis and calculation of cooling.

- Interactive thickness / temperature / position information with a simple mouse click.

- Export animation file to Microsoft Video Player format.

- Cooling calculation.

Pre-distortion of images (option)

- Prediction of printed image deformation.

- T-SIM is able to pre-distort images for printing them on the flat sheet, so that once thermoformed, the images appear true.

- Image projection manager enables projection of multiple images using various projection methods (planar, cylindrical and spherical projection).

- IGES polylines can be projected, distorted / pre-distorted and exported back to IGES.

- 3D VRML models can be also used for image pre-distortion.

- For more information about image pre-distortion, go to the reference manual.

Customer support

- Support through Accuform representatives worldwide.

- Export of internal T-SIM files for easy data exchange via Internet. This facilitates fast customer support worldwide.

Recommended hardware

- T-SIM delivers peak performance on a multicore Intel or AMD based PC with 2 GB RAM.

- T-SIM runs on Microsoft Windows 7/8/10 - 32/64 bit.

T-SIM users

- T-SIM is used by industry leaders worldwide at Boeing, DOW, Eastman, GE, Mitsubishi, MIT, BMW, Delphi Automotive, Riley Medical, Marconi

Communications, PCM, Fabri-Kal, American Standard, IPS Polymer, Illig, Kiefel, Gabler and many other thermoformers.

T-SIM tutorial online

- Click here to open the T-SIM online tutorial

with more information about T-SIM and with simulation examples.

|